Emergency Response Center - ERC

A Proven Solution for a comprehensive SOPs for plant-wide critical alarms, providing a unified platform for notification and response, statistical analysis, and inspection handover.

Challenges in Managing Dispersed Alarms and Events in Factory Systems

The numerous and scattered systems in factories make alarms and events dispersed across each subsystem, making it difficult to efficiently manage and track processing status. More worryingly, if important equipment or processes trigger alarms that are not promptly addressed, it could lead to work safety crises or severe losses.

What kind of solution is the ERC?

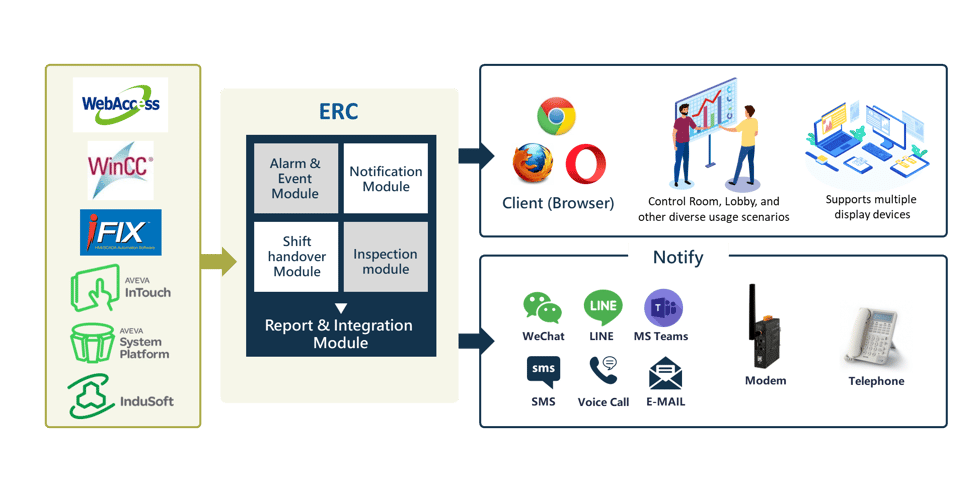

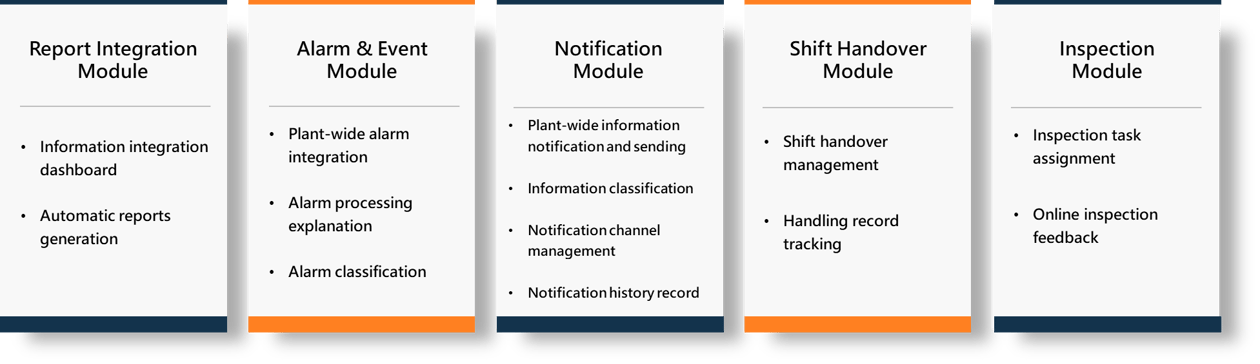

The Emergency Response Center (ERC) is a management platform that integrates all factory alarms and combines automatic report generation and inspection handover functions.

With ERC, you can see all ongoing events, alarms, processing tracking, and trend reports for the entire plant on a single platform. It helps improve response speed and efficiency in managing critical alarms and abnormal events.

Elevate Alarm Management: Real-Time Tracking Meets Strategic Insights

Seamless Integration & Browsing

Seamlessly integrates data from SCADA and databases. Web-based environment allows you to browse in real-time anytime, anywhere from computers, tablets to mobile phones.

Manage alarms with insight

Automatically tallies alarm quantities and levels, and provides graphical reports, covering trend analysis comprehensively. Improves efficiency in personnel management of alarms and abnormal events.

Diverse Notification Methods

6 notification methods at your disposal, with customizable notification conditions. Automatically and accurately deliver "the right message" to "the right person". (Notification methods include: MS Teams, SMS, voice calls, Email, LINE, WeChat)

Real-time Recording and Tracking

Real-time recording and tracking of alarm handling processes, not only establishes response SOPs but also ensures no handover items are missed.

Transform Historical Data into Predictive Insights

All historical alarm data and handling records will be stored in the ERC, providing not only alarm statistics but also contextual insights.

What our customers say

“Our process involves a large amount of toxic gases and liquids. Both company and the government are increasingly focused on workplace safety and the security of critical facilities. The ERC's plant-wide alarm integration, cross-platform notifications, and real-time tracking of handling progress have successfully helped us respond to 'emergency situations' and 'potential safety concerns' promptly, minimizing losses to the greatest extent possible”

“Since we have three plants, and the SCADA brands and versions used in each plant vary. The complexity of integration was high, which made it difficult for us to establish a unified alarm center. After implementing ERC for integration, we can now access alarm data from all three plants on a single platform without having to run around. Furthermore, the alarm notifications are fully automated, allowing for the most efficient use of manpower.”

“ERC helps us automatically compile alarm data and generate reports. Engineers can instantly access real-time alarm trends and quickly formulate response strategies. Additionally, we have configured ERC to notify relevant personnel directly via Teams, email, SMS, and phone calls when an alarm occurs. This saves a lot of time in notifications and speeds up the handling process.”